- Home

- Discontinued

- 3D PP Film and Sheet Extrusion Line

This product has been discontinued and removed from our shelves.

By using PP (propene polymer) as the main raw material, the 3D PP film and sheet extrusion line is designed to produce the film and sheet via special casting and molding techniques. The finished film and sheet come with strong stereoscopic impression.

Features of Our Production Line

1. The screw is specially designed to ensure even plasticizing of raw materials.

2. The molding device can freely ascend and descend. The film and sheet with different thickness can be produced, hence, the quality of film and sheet is improved and the processing range is also expanded.

3. The cooling and forming roller designed with special flow passage adopts unique surface treatment to achieve three-dimensional effect.

4. Our 3D PP film and sheet extrusion line is also equipped with the shearing machine so that the film with different lengths as required by customers is attainable.

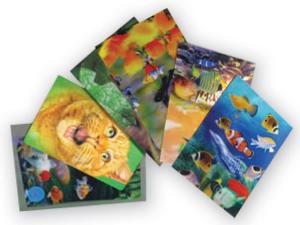

Characteristics of 3D PP Film and Sheet

They feature elegant and top-grade appearance, bright color, distinct layering and artistic effect.

Main Applications of 3D PP Film and Sheet

They are primarily applied to commodities, table mats, top-grade folders, gift box packaging, etc.

Parameters of Our Production Line

Parameters of Our Production Line| Model (mm) SJLM-Z | |

| Screw Diameter (mm) | 90 |

| Length-diameter Ratio of Screw (L/D) | 32:1 |

| Width of Finished Film (mm) | 800 |

| Thickness of Finished Film (mm) | 0.02-1.0 |

| Maximum Extrusion Capacity (kg/h) | 150 |

| Linear Speed of Machine (m/minute) | 20 |

| Total Installed Power (KW) | 120 |

| Overall Dimensions (L×W×H) (m) | 10×2.5×4 |

| Weight (T) | 15 |

Note: The above data are subject to change without prior notice.

- No.136 Nanhuan Road, Xinle City, Hebei Province +86-311-85196308 +86-311-85196310